ball and race coal mill gas

Coal mill pulverizer in thermal power plants

pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

vertical raw mill vs ball mill

vertical raw mill vs ball mill. ... Available fuel: Bituminous coal,lean coal,anthracite. Email: [email protected] Please email or call us for your inquiry. With more than 30 years of manufacturing boilers, the company has formed more than 400 varieties of gas boilers, biomass boilers, coalfired boilers, heatconducting oil boilers, etc.

working of coal mill animation in Nigeria

How Does a Coal Power Plant Work?Bright Hub, Thermalbased power plants can produce electricity from coal or other fuel sourcThe function of the coal fired . ... Working Hours; MonSun : 0:00 to 24:00;, coal ball mill animation in delhi Nigeria, Raymond Coal Mill Animation, ball and race coal mill animation Ball race .

Pulverized coal storage in Bunker and coal handing system

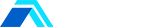

a) Ball mill pulverizing . Ball and Race mill pulverizing. a) Ball Mill . A line diagram of ball mill using two classifiers is shown in figure. It consists of a slowly rotating drum which is partly filled with steel balls. Raw coal from feeders is supplied to the classifiers from where it moves to .

Chap The Babcock Wilcox Company Chapter 13 Coal ...

The Babcock Wilcox Company Steam 41 / Coal Pulverization 131 Chapter 13 Coal Pulverization The development and growth of coal pulverization closely parallels the development of pulverized coalfiring technology. Early systems used ballandtube mills to grind coal and holding bins to temporarily store the coal before firing.

Hitachi Power Europe Service GmbH

Pulverisers for Bituminous Coal Long service life Tube ball mill type RKD The Hitachi Power Europe Service RKD tube ball mill grinds and dries difficulttopulverise hard coals (particularly lowvolatile coals such as lean coal and anthracite). This mill type can deal with approx. 150 t /h of coal. Depending on size and space, the tube ball mill

Flue Gas Denitrification Leads the Champion of Mill

The raymond mill, stone grinder machine and barite grinding mill are new developed pulverizer machine, compared with other mills, its advanced technology has greatly increased the flue gas desulfurization of power plant and becomes the impetus to control emissions of atmospheric pollutants of thermal power plant, improve China's air quality and ...

PPT – BALL MILL PowerPoint presentation | free to download ...

what is a ball mill, its constructuction description, working,etc – A free PowerPoint PPT presentation (displayed as a Flash slide show) on id: 7175b9MGY2M

Package Name : Supply of Gear Box for Ball Race Mill ...

(a) The Bidder must have successfully executed orders for supply of Gear Boxes for Coal Mill to atleast Two different Thermal Power Plants of 60 MW or above capacity, during preceding 7 (seven) years from the date of Technical Bid opening. (b) The above Gear Boxesmust be in operation for last 24 months from the date of Technical Bid opening.

Investigation of the classification operation in a coal ...

This study investigates the effect of changes in coal and airfl ow feed rates on the classifi cation performance that occurs in an industrial scale ballandrace vertical spindle mill in which the pulverisation and classifi cation processes are linked together due to the separator classifi er being an integral component within the pulveriser.

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

Ball Tube Mill Modernization and Performance Components Main

Ball Tube Coal Mill Modernization and Performance Components. Increase throughput, balance coal pipes, increase coal fineness, reduce emissions. ... Click on the Ball Tube Mill Series to view product information. ... Increase Throughput • Balance Fuel Pipes • Increase Fineness • Reduce Emissions.

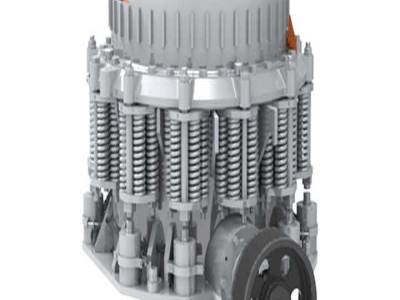

Mining NonFerrous CITICHeavy Industries Co. Ltd

CITIC HIC is a manufacturing base for equipment supply into the Mining and NonFerrous industries. In addition to its own range of mining equipment CITIC HIC also manufactures mining equipment components for other OEM suppliers including FFE Minerals, Metso Minerals, Outotec and others.

Planetary Mills –

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls. The grinding can be performed dry, in suspension or in inert gas.

energy efficiency in thermal power plants coal pulveriser ...

COAL MILL/PULVERIZER IN THERMAL POWER PLANTS, to convert the energy stored in coal into, 1000 rpmType Ball tube Bowl . Live Chat; Ball Mill In Coal Based Thermal Power Plant. pulveriser mill ON A POWER STATION coal ball and rice mill, ball mills in thermal power plant Coal is used thermal, ball tube types of coal mills of thermal . Live Chat

Latest Posts

- حيث التكلفة من فائقة غرامة طاحونة

- لهجة كسارة الحجر

- كسارات التعدين المتنقلة الألمانية

- استخدمت كسارة الفك المحمولة في مصر

- مواصفات الكسارة التصادمية pf1007

- كسارة الهواء pencemaran لوغام

- أرضيات من الرخام طحن بالتيمور

- تصنيع آلات تكسير الحجر الصين

- معدات معالجة مركزات النحاس

- تصنيع مصنع محجر الحجر في الصين

- قدرة منخفضة تهتز شاشة

- كسارات الصخور الصعبة الجزائر

- يستخدم مخروط الفك محطم

- نموذج كسارة الحجر وتكلفة divoire

- أرجوحة مطحنة المطرقة السعر

- company which make mobile crushers in india

- gasparin crusher feeder

- how to smoke heroin in powder form

- heavy belt conveyor for rock

- harga mobile crusher

- 100 tph mobile cone crushers for sale south africa

- craigslist los angeles floor machine used

- working principle of hardgrove grindability index

- apu k choda bangla font

- low silica limestone mines owner in brazil

- ce u ios approved high performance ball mill for sale in china

- how to plan machinery for iron ore mining

- kaolin mining development

- crusher plants emira os of arab states

- digunakan pabrik bola australia untuk menghancurkan marmer