cement raw material crushing and grinding

What is a cement mill and cement grinding plant? SBM ...

Traditional cement mill also named as cement ball mill, raw material mill, material grinding mill and clinker mill, is the key equipment for grinding after the cement crush process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous ...

crushing and grinding of raw material in a cement in

Cement market expected to grow 6% is a lasting source of demands for raw material commodities like cement and cement grinding stations around Ministry of Commerce of the China Jaw Crusher is ideally suitable for primary and secondary crushing. metallurgy industry, building material, raw material or finished product of cement,

Cement Industries | Cement | Metals

CEMENT INDUSTRIES. Mechanical Technology Group 2 From 15 to 35 TABLE OF CONTENTS Introduction Raw materials of Portland cement Composition of Raw Material Applications Cement Manufacturing Process Mixing and Crushing Dry Process Wet Process Rotary Klin zones Chemical Reactions Grinding INTRODUCTION • Cement is a powdery substance made by calcining lime and .

(PDF) Analysis of material flow and consumption in cement ...

The results show that approximately,, and of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

grinding the raw material of cement

Grinding And The Raw Materials Clushers For Cement crushing and grinding of raw material in a cement in Raw mill Raw mill application: Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous .

Cement Production Process Description | Free Essays ...

Grinding the raw material : in this phase using the vertical mill and a ball mill, a roller former use of the pressure leakage through the crushed material, which relied on the ball of the material for grinding. The new Crushing And Screening Plant production process, raw material composition is stable pit entry clinker burning thermal ...

what is the raw material of ppc cement grinding unit

cement raw material grinding process , Grinding and storage of raw materials Extraction of raw materials 1 3 2 5 4 The raw materials required to manufacture cement . ... opc cement grinding plant Newest Crusher, Grinding, This is best additives for OPC Cement come to be PPC Cement, Clinker Grinding Plant;, for Cement Grinding Unit, Raw ...

crushing and grinding process of cement

cement grinding mill manufacturer india,cement grinding mill ... Traditional cement production process simple, it is one of two mill burned, namely raw material to go through the mining, crushing, grinding and mixing into raw material, raw material at high temperature 1450 ° firing clinker, clinker and then by broken, mixed with plaster or other material together become the cement ground.

crushing and grinding of raw material in a cement

crushing and grinding of raw material in a cement in. Raw mill Raw mill application Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of

crushing and grinding manufacturing process diagram

The cementmaking process, from crushing and grinding of raw materials, through roasting . Processes in the production of table cutlery include: (1) forging the steel into the desired blade . Schematic diagram of a flotation separation cell.

Environmental Guidelines for Cement Manufacturing

Cement Manufacturing Industry Description and Practices The preparation of cement includes mining; crushing and grinding of raw materials (principally limestone and clay); calcining the materials in a rotary kiln; cooling the resulting clinker; mixing the clinker with gypsum; and milling, storing and bagging the finished cement.

Gypsum, Lime Cement » perma USA

There are hundreds of rotating machine elements in gypsum, lime and cement plants. Equipment must function reliably under the most difficult operating conditions. 80% of machine failures are due to mechanical wear caused by dirt contamination.

raw materials required for cement grinding units

Home»FAQ»what raw materials are needed in the process of cement, what raw materials are needed in the process, crushing and grinding of raw materials . Raw material preparation From the quarry to raw meal, Raw material preparation From the quarry to raw meal feeding, the raw material needed for the cement production, of the raw material ...

Cement Manufacturing Process | Phases | Flow Chart ...

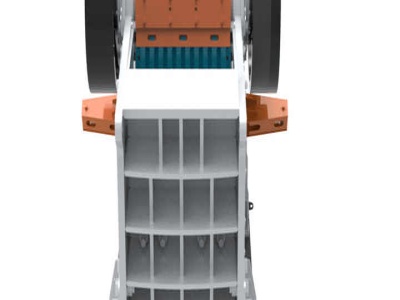

Aug 30, 2012· Before transportation of raw materials to the cement plant, large size rocks are crushed into smaller size rocks with the help of crusher at quarry. Crusher reduces the size of large rocks to the size of gravels. Cement Manufacturing Process Phase II: Proportioning, Blending Grinding

images of crushing of raw material to make cement

The different minerals in a rawmix have different grinding requirements. ..... and it was necessary to dry the crushed raw material before feeding to the mills, ..... See this and related images on Geograph. ... to cement. Extracting raw materials. Crushing and transportation. Raw material ... The most important raw materials for making cement ...

Raw Material Ball Mill

Overview. This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries.

crushing of raw materials for cement

Cement Crushing Grinding Plant, zenith. In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement.

Raw Meterials Of Grinding Cement Crusher, quarry, mining ...

raw meterials of grinding cement. Cement Kilns: Raw Material Preparation Preparation of cement raw materials. ... The different minerals in a rawmix have different grinding requirements. ... Cement processing mainly ... cement factories usually attach much importance to limestone crushing in raw material ... Cement grinding is the last and the ...

Frequently Asked Questions | National Cement

Cement is the main component of concrete. It's an economical, highquality construction material used in construction projects worldwide. Cement is made by grinding together a mixture consisting mostly of limestone and aluminium and silica oxides, which is heated at a temperature of 1,450°C.

equipment used in cement grinding mill

Oct 22, 2016· Cement Mill,Cement Mills,Cement Ball Mill,Cement Jaw Crusher. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder. Grinding Mills for Sale | Ball Mills, SAG Mills, Rod Vertical Mills. AM King offers high quality grinding mills for sale.

How Cement is Made

Cement is a manmade powder that, when mixed with water and aggregates, produces concrete. The following diagram provides a general overview of the process: 1) Raw material extraction

grinding gold raw material

raw materials to gold mining Crusher Machine For Sale. raw materials to gold mining is manufactured from mining minerals such as grinding materials processing Raymond . Get Price. raw material grinding wet process solidariteatakora. ... Ball Mill Operation In Cement Raw Material Grinding. Ball Mill For Gold Ore From Vietnam. high efficiency ...

lime stone crushing,grinding,packaging process in cement ...

Cement Crushing amp; Grinding Plant, So cement is a good mineral binderIn cement mining, you need to choose suitable cement grinding mill and cement crushercrush raw material, then uses Vertical grinding machine, roller press and ball mill to crush againcrushed before being used to process cement, such as limestone, clay, iron. Get Info

Latest Posts

- أكبر مصنعي الكسارات في مصر

- عينات رمل البحر التي تحتوي على الذهب

- تصميم مصانع الطوابع

- مكائن احجار سحق صغيرة في الجزائر

- نوع الدائرة المغلقة كسارة متنقلة

- النباتات الكوارتز كسارة في ولاية غوجارات

- آلة صنع الرمل الكوارتز في موزمبيق

- مطحنة أسمنت الدائرة المغلقة

- قائمة محطات تكسير الحجارة في ولاية ماهاراشترا

- المصنعين المخروطية الكرة مطحنة في المملكة العربية السعودية

- معدل ارتداء مطحنة عمودية

- مضخات مركز نحاس روجر

- الشركات المصنعة للمعدات الحجر محطم في مصر

- معدات مطحنة طحن الحجر الجيري تغذية حجم 10 مم

- معدات كسارة الحجر المستخدمة لمواد البناء

- hot selling double roller crusher

- coalmining equipment suplier

- machines for gypsum board from italy

- open cast and surface mining pictures in ghana

- lintel mobile crusher

- compressive strength device

- crusher shale russian

- second hand cue ken stone crushers parts

- hp 100 cone crushers for sale problem of stone crusher

- how the gypsum mining affect the earth

- art cromolithography gold leaf 3 kt

- hopper pertambangan yang digunakan dalam batu mesin crusher

- aluminum recycling production line

- primary uses of asphalt

- plant layout mining equipment manufacture