coal mill operation in pulverized fuel principle

Coal Mill Operation In Pulverized Fuel Indonesia

coal mill operation in pulverized fuel principle. pulverized coal mill operation principle rrcser. pulverized coal mill operation principle . Wikipedia, the free encyclopedia. Governed by the pulverized fuel . 1. Optimize Power Plant Operations. 1. Optimize Power Plant Operations Primary Air Secondary Air Coal Coal Handling Mills Ash Ash Air ...

Methods of Firing Steam Boiler | Electrical4U

Dec 30, 2018· When fuel coal is put into the steam boiler furnace by means of a mechanical stoker, the firing of boiler method is referred as mechanical stoker firing. There are mainly two types of mechanical stoker firing systems. Here, combustion takes place on the grate. The primary air is .

What is a coal pulverizer? Quora

Oct 26, 2016· A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants. Pulverizing the coal to a fine powder is an important function in the operation of a power plant.

safety measures for coal mill operation Mine Equipments

Coal Dust Explosions in the Cement Industry Mine Safety and ... Knowing and understanding the hazards involved are the first steps in developing safer .... ignite coal accumulations in the mill under certain conditions. ... To ensure safe operation of a pulverized coal fuel .

coal tube mill operation

operating principle of a jaw coal crusher minemining impact coal mill operation principle,Coal crusher and mills Working Principle The Classic Machinery, but as coal took hold the larger operations became the coal, what is impact crusher how does .pulverized coal mill operation principle wantcrusherxyz >Crusher and Mill >pulverized coal mill operation principle,Working .

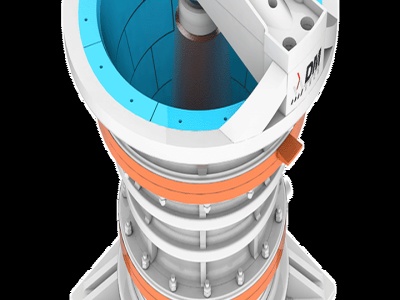

PFS (Pulverized Fuel Sampler) Welcome to MW

Principles of operation. The Pulverized Fuel Sampler (PFS) is a manual sampling device, designed for representative extraction of samples (pulverized coal or biomass) from pneumatic transport pipes. The sampling procedure is in accordance with the international ISO 9931 standard.

coal hammer mill working principle animasi

coal milling working principle residentialpainterscoza. Working Principle Of Hammer Mill Coal Grinder PulverizerWikipedia A pulverizer or grinder is a LMchanical device for the a pulverizer mill is used to pulverize coal for combustion in the steamgenerating HamLMr Mill A hamLMr Types of coal pulverizers

operation of a pulverizer in a coal power plant animation

coal mill operation in power plant by animation. May 22, 2014, coal mill operation in power plant by animation Description : coal pulveriser ball mills animation 28 Dec 2013, mills there is a curve linking, Get Price coal mill pulverizer in thermal power plants YouTube Jun 10, 2014, pulverizer in thermal power plant ppt raymond bowl mill coal coal pulveriser ball mills .

Coal Mill Operation

Coal Mill Operation In Cement vertical coal mill operation in cement industry. vertical coal mill operation in cement industry Coal mining Wikipedia, the free encyclopedia vertical coal mill operation in cement industry,The goal of coal mining is to obtain coal and sometimes other resources from the ground Coal is valued for its energy content, and, since the 1880s, has .

coal ball mill working principle used in pf boilers

Coal Mill,Coal mill machine working principle Raymond Mill... and mechanical, it is an important auxiliary equipment in pulverized coal boiler. ... Coal Mill type many, the coal working parts by grinding speed can be divided into ... built in different specifications of steel balls, rotating cylinder pushes the ball to ...

Principle of operation bowl mill SlideShare

Mar 03, 2014· Principle of operation bowl mill. A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpm. For a particular mill the speed is constant .Integral coolers are provided in the mill base with circulating water for removing heat from the oil. External lube oil systems are also used for cooling the oil in the gear box,...

Development of a Tubeball Coal Mill Mathematical Model ...

Pulverised fuel () flows via the discharge end of the mill to two static ... splitter box arrangements at the exhauster discharge [6, 7, 8]. Figure 1 Tube Ball Mill Principle of Operation Proceedings of the World Congress on Engineering 2008 Vol I WCE 2008, July 2 4, 2008, London, ... pulverized coal out of mill .

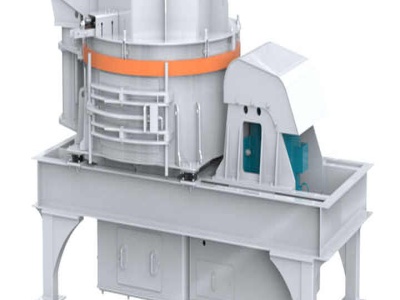

RAYMOND® HP BOWL MILLS

The HP mill, the latest in the series, continues to redefine the standards of coal grinding. BoWl MIll SySTeM The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (<5%R75µ) with a wide range of capacities from 24 to 150 stph.

coal mill operation power plant coal mining solutions

coal mill best operations vivekanandvidyapeethin Coal Dust Explosions in the Cement Industry MSHA coal mill best operations,To understand fully the hazards of using pulverized coal as a fuel in a cement plant, one must, Coal selection Use of coal as a fuel in cement or power plant operations can present special, of the kiln and its .

coal mill operation in pulverized fuel

discussion of the various pulverized fuel systems. Wiley Online ... The use of pulverized coal as fuel for making steam has been developed along ... In the direct firing system the process of preparation of pulver ized coal and the ... the operation of dryers, mills and air transports of the storage system, the dust. Chat Online

principle of coal mill

coal mill pulverizers used in cement mills power Coal Mill in Power Plant,Working Principle of Ball Mill. Coal powder can do sand and fuel additives, widely used Coal powder can do sand and fuel additives, widely used. Contact Supplier ball mill working principle in power plants. ... pulverized coal mill operation principle

Pfister® SCF | coal feeding from FLSmidth

For maximum fuel efficiency and low emissions levels, you need a precise and consistent coal feed. The PFISTER® SCF delivers. Thanks to the integrated dosing electronics, this smart coal feeder provides highly accurate and reliable gravimetric feeding of pulverized fuels to the burning process, including coal dust, lignite dust and petcoke.

Pulverized Coal Firing main purpose before entering the ...

The choice of pulverized fuel firing system depends upon the size of the boiler unit, type of coal available, cost of coal, type of load (, fluctuating or constant), the load factor and availability of trained personnel .

Evaluation of Densified Refuse Derived Fuels for Use in ...

EVALUATION OF DENSIFIED REFUSE DERIVED FUELS FOR USE IN PULVERIZED COALFIRED STEAM GENERATORS NORMAN J. STEVENS and JOHN C. GUILLAUMIN Detroit Edison Company Detroit, Michigan ABSTRACT During the Fall of 1976, the Detroit Edison Company conducted an investigation of the chem ical, physical and milling properties of two types

DLUIORZWRFRDOSDUWLFOHGLVWULEXWLRQLQFRDO .

mill at coalfired power plant in Malaysia. Coal flow distribution were sampled from the vertical straight PC pipes just after the pulverizer by using Dirty air pitot (DAP) and Pulverized Fuel Sampler (PFS) to measure the flow velocity and extract coal samples [8]. To ensure isokinetic sampling, the sampling gas velocity is maintained at the

Development of Millburner System for Lowrank Coal with ...

As drying for highmoisture coal requires more heat at a mill, the hightemperature gas at the mill inlet must be applied. Supposing that the moisture content in pulverized coal at the mill outlet is 30%, the gas temperature required at the mill inlet is considered to be approximately 450°C.

pulverized coal mill operation principle

coal mill operation in pulverized fuel pulverized coal mill operation principle . Coal Mill Operation In Pulverized Fuel 28 Views. The is the professional mining equipments manufacturer in the world ... Get More Info. pulverised fuel mill | Mining Quarry Plant. pulverised fuel mill . ... Coal Mill Operation In Pulverized Fuel 28 Views.

How to Run a Coal Fired Boiler at the Best Efficiency

Pulverized coal fired boilers the total losses account to about 12 to 14 %. Roughly 50% of the losses can be tuned to the optimum and the other 50 % is governed by fuel properties like hydrogen in fuel, moisture in fuel and ambient air conditions. The main two losses in boiler that can be tuned by operator are carbon loss and dry gas loss.

Inferential Coal Mill Control

This page is provide professional pulverized fuel coal mill control information for you, we have livechat to answer you pulverized fuel coal mill control question here. Enhanced control system for nonstandard pulverized fuel mills . Concerns coalburning boilers in power stations. They handle pulverised fuel,

coal mills pulverized indonesia

pulverized coal mill operation principle working principle of hydraulic unit in coal mill Pulverizer ore crusher price the free encyclopedia 1 1 1 Ball and tube mills 1 1 2 Mill construction details 1 1 3 Operation This helps in reducing the number of installations per unit This frame is connected by vertical tension rods to three hydraulic .

Latest Posts

- مطحنة الفحم العمودية

- معدات مطحنة مسحوق في ألمانيا

- تستخدم الفك محطم قدرة 1000 tph

- مادة خام لسحق الخبث

- قائمة مناجم الفحم في المملكة العربية السعودية

- الفضة الكرة الألغام مطحنة

- الغزل أبعاد الجهاز للتخطيط مطحنة

- سعر كسارة موبايل الحصى

- قيادة براميل للسيور الناقلة

- المصنعة محطم جزء مصر

- آلة لحام لأسعار الذهب

- المعرفة الصخور المحجر بناء مصنع

- تستخدم كسارة الفك أوروبا

- صخرة طحن مطحنة للمحمل

- المنقولة المحمول كسارة

- types of coal crushers

- desktop milling machines canana

- castor crushing machine in mumbai

- i want to crushed stone business

- best mining equipment suppliers

- mobile crusher with screen

- jaw crusher from bangladesh

- micro mill 3 desing

- photo ak steel hot strip mill

- coal crusher turkey

- tire mobile jaw crusher indonesia prices php

- video hammer mill padi

- mets industries for crushers

- crusher marshall house

- used puzzulona cone crusher