how mill pa inlet temperature effects with imported coal

Experimental Study on Operation Regulation of a Coupled ...

The heat exchangers used to heat condensate are called low temperature economizers (LTEs) or low pressure economizers (LPEs) and called front located air heaters (FAHs) when used to preheat air. Wang et al. [10,11] analyzed the energy saving effects of LPE applied on coal–fired units. Lu et al. [12] optimized an FAH system and analyzed its ...

Hazard and Operability study in Boiler System of The Steam ...

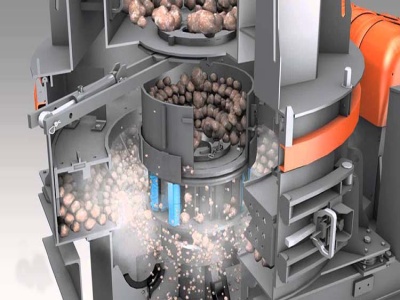

coal pulverize comes first in the capacity of coal in coal ssilo. Separator to separate fine coal and coal that still needs to be processed further and the coal that was not applicable. Air inlet as the air supply, air pulverize requiring fixed temperature for the process, so before entering the air through the pulverize in pprimary heating wwater heater up to a certain temperature.

MSHA Heat Stress Heat Stress in the Mining Industry

You are more likely to suffer from heat stress if you are beginning a new job in a high heat environment, have had a heatrelated illness before, use personal protective equipment (respirator, suit), take certain medication or are over 45 years old. Why is heat stress a health hazard? Severe heat stress may lead to death if not treated right away.

IMPROVING BOILER EFFICIENCY BY USING AIR PREHEATER .

Abstract: Air preheater is a heat transfer surface in which air temperature is raised by transferring heat from other media such as flue gas .Hot air is necessary for rapid combustion in the furnace and also for drying coal in milling plants.

ball mill inlet temperature

ball mill inlet temperature Ball Mill Inlet Temperature Bing rkelectricalscoin. inlet and outlet temp in mill to avoid mill, What is the effect of coal mill outlet temperature, ...

PLANT OPERATIONS AND PRODUCTIVITY .

♦ The leakage from raw mill outlet to ESP inlet is about 30%. ♦ Reduce the leakage to about 20% by arresting the false air points, resulting in power saving of ESP fan. ♦ Higher quantity of the coal transport air to kiln and PC firing. ♦ Quantity of the coal transport air was reduced in phases.

Solenoid Valves Basics

The solenoid valves have two ports (one inlet, one outlet) and only one orifice (seat) allowing fluid control. a. 1 port inlet fluid P 1 port outlet fluid A 3 Ways These solenoid valves have three ports (one inlet, one outlet and one exhaust) and two orifices (seats) allowing fluid control. a. 1 port inlet fluid P 1 port outlet fluid A

CoalGen 2010 PreAir Heater Control of SO and Related ...

CoalGen 2010 PreAir Heater Control of SO 3 and Related Condensables Charles A. Lockert, Breen Energy Solutions, 104 Broadway Street, Carnegie, PA 15106 Greg Filippelli, and Marty Dillon, ADA Environmental Solutions, 8100 Southpark Way,

how to calculate coal mill capacity

how to calculate coal mill capacity. We produce parts and components for the shearer and boring machine manufacturers, and provide technical services, and provide shearer picks, import shearer picks, import boring machine picks, German import picks, rotary pick cut Teeth, Pittec picks and other coal mining equipment machinery.

BioProcessing Case Study: Sampling, Monitoring, Control ...

Measure of reactor inlet, C. in, outlet CO composition determines Gas solubility, C*, depends on headspace pressure reactor temperature which are monitored and controlled Other variables that contribute to G/L mass transfer – Gas/liquid holdup – Bubble size/number distribution effects a. L – Gas velocity (mean residence time) effects ...

Optimising fuel flow in pulverised coal and biomassfired ...

Ensuring the correct/optimal raw coal size and its supply to the mill 16 ... pressure 17 Throat clearance and pulveriser air flow 18 Classifier maintenance 19 Pulveriser inlet and outlet temperature/ combustion air temperature 20 ... Optimising fuel flow in pulverised coal .

85 e type coal pulverser

Coal pulverisers' performance optimisation is an important process in power generation plants. Pulveriser operation is costly; reliability and availability is key to power generation and Figure : Mill crosssection overview (Babcock Etype). . The design mill inlet and outlet temperature is 245oC and 85oC.

Hazard and Operability study in Boiler System of The Steam ...

power plant (PLTU). Pulverizer plant serves to break chunks of coal into the coal ash was then fed to the burner. Type of feed coal into a pulverize is cleaned with a value product pulverize optimum 30%. The percentage of this value greatly affects the production of steam in the boiler.

coal mill pulverizer plug in chute

coal mill pulverizer plug in chute Pulverizer Operation Performance and Testing |. Effect of PRB on Mill Operations – Significantly higher PA temperatures required due to high moisture in PRB – Significantly higher volume of coal feed due to lower BTU in PRB and lower bulk density of PRB – PRB is Sticky ‐ it plugs chutes and hoppers or anyplace it falls onto a ledge or ...

coal crusher with hot air inlet

Function Of Coal Crusher function of four roll coal crusher gibma. primary crusher for coal Stone Crusher Price ZME machinery. which is also known as double roll crusher, what is the function of spring in cone crusher; inlet chute for roller crusher .Serise Four Roller Crusher For Stone,Coke,Coal 2016 Four Roller Crusher Stone and hot air comes into mill through air ...

prb coal maximum mill air temperature

When processing high moisture PRB coal PA temperature of over 600°F is desired to ... Get A Free Quote. ... Effect of PRB on Mill ... Pulverizer inlet/outlet air temperature at above normal full load coal and air flow. 4. Mill ... Maximum coal flow at which ... Get A Free Quote.

Latest Posts

- سعر آلة تكسير الرمل في مصر

- آلة مطحنة الكرة الرنين

- مورد معدات التعدين في المملكة العربية السعودية

- المطارق كسارة العرض اسطنبول

- شركات تعدين البوكسيت العالمية

- maquinas de mistura de concreto em mocambique

- شركات محاجر الجرانيت في مصر

- تركيب آلة محطم

- مطاحن طحن فائقة الدقة للغوار

- غسالة الذهب الصغيرة المتنقلة

- آلة لطحن براثن السيارات

- آلات الأسلاك كسارة الحجر

- آلة غسيل وغربلة

- كسارة الحجر اليدوي السعودية لتصنيع الرمل

- تهتز صيانة كسارة الشاشة

- grinding machines for porridge

- used smoll milling machine for sale in ct

- objectives of tororo cement industry

- steps of designing jaw crusher machine using solidworks

- stone crusher plant in massachusett price

- pgl acero china

- britador de resíduos sólidos preço

- labscale jaw crusher dengan saringan

- photos of jaw crushers in opperation

- por le crusher malaysia supplier

- hot sale rotary dryer for wood chips rotary drum dryer for wood chips rotary

- non woven abrasive manufacturer

- pu shoes making machine

- aluminum can crusher blower

- harga grinding stone maret 2014