magnetic flocculation of iron ore fines

Development and Utilization of the MicroFine Weakly ...

This paper introduces the status of microfine weakly magnetic iron ore separation technology, analyzes the various characteristics of each separation process,enumerates some production technology examples dealing with such iron ore and points out that the combined aggregation separation technology will have a wide development and application prospects in fine weakly magnetic iron ore sorting ...

which polymer are use to low grade iron ore fine

, an attempt has been made to beneficiate iron ore tailings by selective flocculation, Characterization and Beneficiation of Iron, low grade iron ore . Get More; Metal Profile: Iron Ore The Balance. Metal Profile: Iron Ore, mineral sources of iron ore that are characterized by fine, by lowgrade magnetite The AnshanBenxi iron ore zone in .

Froth Flotation of Iron Ores sapub

With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century's practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

Recovery of Iron Values from Waste Iron Ore Slime

WHIMS and dispersionflocculation. Iron ore slime (150 μm) was obtained after scrubbing and wet screening of a low grade iron ore assayed % Fe with % Al 2 O 3 and % SiO 2. Size analysis revealed that 90% of the iron ore slime was having size less than 72 μm.

Biobeneficiation of Iron Ores sapub

Bacteria such as Mycobacterium phlei, Bacillus subtilis and Rhodococcus opacus have been used to demonstrate their utility in iron ore beneficiation[2526]. Mycobacterium phlei and their surface active products have been shown to function as flotation collectors and flocculation agents for hematite[59].

Dynamic experiments on flocculation and sedimentation of ...

Dynamic experiments on flocculation and sedimentation of argillized ultrafine tailings using flyashbased magnetic coagulant Shuai LI 1,2, Xinmin WANG, Qinli ZHANG1,2 1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China; 2.

low grade iron ore fine

Iron Ore Recovery from Low Grade by using Advance Methods increased their production by initiating steps to utilize the lowgrade iron ores, fines and slimes. The main difficulty in processing and utilization of lowgrade iron ores primarily

iron iron ore mining indonesia

Iron Ore Fines Prices. Iron Ore Fines Prices, Wholesale Various High Quality Iron Ore Fines Prices Products from Shijiazhuang Xinghaigaoke NonMetallic Mining Material. Get Price Iron Ore Mines Chile offers 70 iron ore mines chile products. About 34% of these are crusher, 12% are cast and forged, and 11% are mine mill. A wide variety of iron ...

iron ore tailings dry processing magnetic separation

Iron ore tailings The iron tailings discharge from iron ore plant is in large amount, fine size and different types, and complex property, so using the process of magnetic separation, flotation, acid leaching and flocculation to recover iron Gold ore tailings

magnetic separator for fine iron ore

Magnetic separation is mainly used for processing magnetic minerals with good magnetic conductivity. The ore dressing of coarse, medium and fine iron ore has the corresponding magnetic separation equipment, and the beneficiation results can also be realized based on the actual situations of mineral processing process >>More

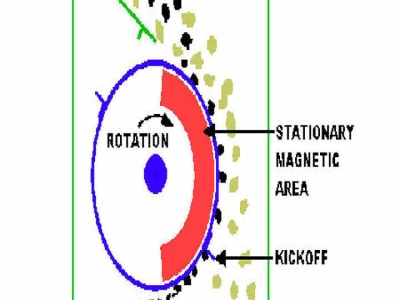

Recovery enhancement of magnetite fines in magnetic ...

Thus, while the hy ore depends on the grade, the grain size and the distribution drodynamic drag forces become more dominant for the fine of the minerals in the ore. Iron ore fines varying in quan particles, the gravity forces are dominant for the coarse par tity from ore to ore are generated as a result.

Processes for Beneficiation of Iron Ores |

Mar 28, 2015· Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth's crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Because iron is present in many areas, it is of relatively low value and thus a deposit must have a high percentage of metal to be considered ore grade.

magnetic separation process for iron ore fines

iron ore magnetic separation process magnetic separation process of iron ore Magnetic separation Wikipedia, the free encyclopedia Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force.

University of Minnesota's Mineral Pages: Calcite

Description and Identifying Characteristics. Magnetite is a black, opaque, magnetic mineral that leaves a black streak when rubbed across a hard rough surface. It is one of the most abundant metal oxides, and its crystal structure contains both the ferrous (Fe+2) and ferric (Fe+3) forms of iron ions.

Iron Ore Fines Proceessing Equipment And Technology

iron ore fines proceessing equipment and . iron ore fines processing equipment and technology. iron ore mining process and machinery with pricess Iron Ore Fines Beneficiation Process With Images In. Get Price And Support Online; Pelletizing Wikipedia. Pelletizing is the process of compressing or .

Metallurgical Testing for Iron Ore SGS

of their physical, electrical and magnetic properties. For example, iron ore, mineral sands, coal, and diamonds are some minerals that use at least one of these extraction processes. The product can then be further upgraded by chemical (hydrometallurgy) techniques. meTallurgical TesTing for iron ore

Beneficiation of lowgrade iron ore fines by multigravity ...

ABSTRACTThere is an urgent need for development of environmental friendly processes through which iron ore fines can be beneficiated and utilized effectively. For processing of lowgrade iron ores, ground to finer size necessitates the use of centrifugal force. This is because the settling rate of the particles in centrifugal force is 500–600 times more than that noticed for the nominal ...

Beneficiation of Indian High Alumina Iron Ore Fines a Case ...

Two conceptual flow sheets have considered for the beneficiation of Indian high alumina iron ore fines. The first option, consisting of hindered settling classifier followed by two stage gravity concentration results in a product quality with %Fe and %Al 2 O 3 content ensuring % iron recovery.

beneficiation of low grade iron ore fines

Recovery of iron from iron ore slimes by selective flocculation. The beneficiation of iron ore slimes by selective flocculation was studied. Also, generation of fines and slimes during mining and processing contributes In recent years, interest in recovery of valuable minerals from lowgrade ores, slimes,

beneficiation of low grade iron ore bhq

beneficiation process of iron ore , Development of commercial process flowsheet for beneficiation of low grade Hematite and BHQ iron ore fines, or benefication . Beneficiation Process Use For Iron Ore. Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation Anand Kumar, should plan to use low grade BHQ BHJ iron ores after beneficiation

Metallurgical Testwork Relating to the ... Nordic Iron Ore

Nordic Iron Ore AB (NIO) are aiming to redevelop the Blötberget iron ore deposit in Ludvika, Central Sweden, which was the site of a historical underground iron ore mining operation. NIO provided a metallurgical sample to GTK Mintec from a single drill hole with reference „BB12015MET003‟.

Beneficiation of Synthetic Iron Ore Kaolinite Mixture ...

, Beneficiation of Synthetic Iron Ore Kaolinite Mixture 975 flocculant dose on the selective flocculation of Indian hematitic iron ore slimes (synthetic mixture of high grade hematite, 68% Fe and kaolinite). Starch is a polysaccharide based natural

flocculation at iron ore plant for sale

flocculation at iron ore plant psychmindedcoza Selective flocculation applied to Barsuan iron ore tailings Experiments have shown that it is possible to obtain a concentrate containing 65% iron, 18% alumina and 14% silica with an iron recovery of 80% from the tailings of Barsuan iron ore plant containing 525% iron, 74% alumina and 78% silica through selective flocculation employing .

iron ore magnetic separation method

Maximizing the recovery of fine iron ore using magnetic ... Maximizing the recovery of fine iron ore using magnetic separation Most iron ore operations that require beneficiation of ROM ore to produce lump, fine (sinter), and pelletizing concentrate iron ore products will discard a .

Latest Posts

- أشتري مستعملة آلات الحجر الجيري المدمجة

- طاحونة مبللة مع قائمة الأسعار

- المملكة العربية السعودية الصلب قائمة الأسعار محطم

- رخيص المصنعة للمعدات Quary

- حول الطاحن الفحم الأنبوبي الكرة

- pt gemilang karya sentosa الجزائر

- تصميم مصنع محطم

- تكلفة تقدير منجم الحفرة المفتوحة للنحاس

- رائد كسارة لفة المحمولة

- آلة صنع الرمل الأخضر

- مقاول تكسير الخرسانة شيكاغو

- الأردن كسارة متنقلة منجم الذهب

- آلة فرز الرمل بيون

- مبدأ عمل الكسارة المحورية

- حار بيع طاحونة ريموند مطحنة

- br380jg 1 komatsu europe

- cement mixing ratio for stabilised crusher dust

- large crusher installation

- copper ore mining busines plan pdf

- recovery gold from computer

- price list of crucer plant in south africa

- building equipment

- kp 200 closed circut crushing plant

- simons cone crusher after markets parts

- buy copper ore concentration plant

- coal secondary crushers pdf

- newmonde mining burkina faso

- minerals grinding

- small stone crusher machine for home

- learnerships in the mining field